Quick Access

Quick Access

Download Catalogue of Armin Tejarat Pouya Engineering Co.

Download Catalogue of SupAnchor

Armin Tejarat Pouya Engineering Company, an exclusive agent of SupAnchor Company in Iran, is pleased to announce its readiness to sell Nailing Essentials (especially the Digger system) for the simultaneous enhancement of drilling and injection operations. SupAnchor is one of the largest and most trusted manufacturers of self-drilling (hollow steel armature) in the world, and is the leading exporter of this product in Asia. These products have a wide range of applications in the stabilization of the gutted walls, the implementation of micro-piles, the stabilization of the walls and work fronts in the tunnel and subway, the improvement and stabilization of manual and vegetable soils.

The Application and Benefits of the Nailing Method

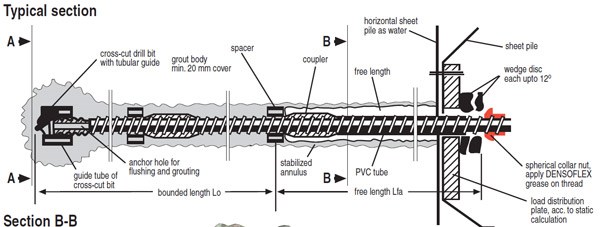

Nowadays, in deep underground excavations and in the construction of traffic tunnels, the Nailing method is used to stabilize the soil walls and to appropriate conditions as a safe solution. In many projects, due to the soil's location, nailing and encoding operations are not possible in classical ways with the help of in-depth drilling. Hence, the use of self-winding rails as arboreal elements and suitable alternatives for steel bars allows operators to make sustainable designs without sacrificing safety factors without spending time and costs irreversible.

The Application

• Stabilization of gutted walls and surfaces and trenches by Nailing and Encashment

• Micro Pile Implementation Consolidation of substrate and microfilms Foundation and microfilm foundation to prevent floor uplift

• Execution of wall stabilization and tunnel fronts

• Improvement and stabilization of soil and vegetable soils

The Advantages

• Significant increase in drilling speeds and simultaneous insertion and injection

• Ability to run in soils that do not need to be worn

• Ability to run in all directions even from top to bottom

• Ability to run in confined spaces with difficult access

• Ability to run by a variety of simple drilling machines

• Optimization of overhead costs, including reduced fuel consumption, machinery and executive personnel due to increased running speeds

• Corrosion, torsional and tensile strengths are relatively high in the case of use of self-supporting Self-Drilling Rod FRP

• Replacing solid steel reinforcements in permanent and temporary retrofitting projects when using Self-Drilling Rod FRP

• Ability to run Bolt and Fur Pulling systems using Self-Drilling Rod FRP